limitations of rebound hardness test|bounce ball hardness testers : member club While it is well known that moisture content, surface finishing, and concrete maturity strongly affect the test result, the effect of the stress state has not yet been studied and is found in this research to be a further parameter affecting the test reliability.

Among the most commonly used sterilization equipment in dentistry are Autoclaves. This article explores the various types of Autoclaves and their significance, particularly for .

{plog:ftitle_list}

dispositivo de esterilización y de doble puerta para el mantenimiento fiable de las condiciones de sala limpia mediante la separación de las zonas limpias y contaminadas.

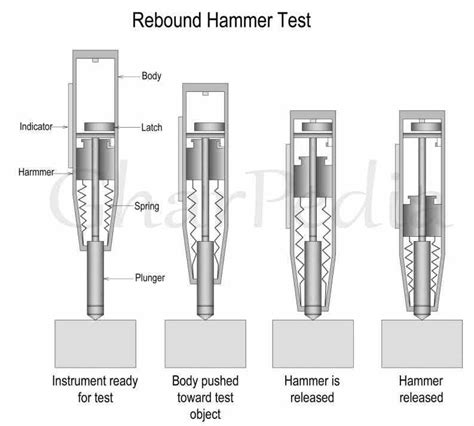

Rebound hammer test method is based on the principle that the rebound of an elastic mass depends on the hardness of the concrete surface against which the mass strikes. The operation of the rebound hammer is shown in figure-1. The Rebound Hammer Test is a non-destructive method for assessing the strength and surface hardness of concrete. It involves complex principles, mechanics, calibration steps & safety considerations to obtain .Rebound hammer test method is based on the principle that the rebound of an elastic mass depends on the hardness of the concrete surface against which the mass strikes. The operation of the rebound hammer is shown in figure-1. The Rebound Hammer Test is a non-destructive method for assessing the strength and surface hardness of concrete. It involves complex principles, mechanics, calibration steps & safety considerations to obtain reliable results.

rebound hardness tester

rebound hardness test procedure

Disadvantages of rebound hammer test. The disadvantages are that the results obtained are based on a local point and it is not directly related to the strength and the deformation property of the surface. The spring and probe arrangement will require regular cleaning and maintenance and the flaws cannot be detected with accuracy. Also Read . While it is well known that moisture content, surface finishing, and concrete maturity strongly affect the test result, the effect of the stress state has not yet been studied and is found in this research to be a further parameter affecting the test reliability. One such type of the non-destructive test on concrete structures is the Rebound Hammer Test. The Rebound Hammer test can be defined as the test that is conducted to evaluate the compressive strength of the existing concrete structure particularly for .

The Concrete Rebound Hammer Test, also known as the Schmidt Hammer Test, is a widely used non-destructive testing method in the field of construction and civil engineering. This test provides a quick and convenient assessment of the .

Schmidt's Rebound Hammer is a nondestructive test which is used to assess the compressive strength of concrete using rebound index. Surface hardness test was done on different concrete. What is the Rebound Hammer Test? The rebound hammer test, also known as the Schmidt hammer test, checks concrete surface hardness. Developed by Ernst Schmidt in the late 1940s, it is used to measure compressive strength. A spring-loaded hammer strikes the concrete, and the rebound distance is measured to estimate strength. The classic Schmidt rebound hammer is the most popular nondestructive method to measure concrete surface hardness, while the Leeb rebound hammer has been extensively studied in geological and metallographic fields over decades, and its use for testing concrete is almost not known.

lame clin autoclave

leebs hardness chart

lame cloture bois autoclave

Limitations of Rebound Hammer Test: 01. The Smoothness of the Surface: Rebound hammer has to be used against smooth and formed surface. It is not applicable for the open textured surface, i.e. a trowelled surface. It should be rubbed smooth with an emery stone. 02. Size, Shape and Rigidity of the Specimen:Rebound hammer test method is based on the principle that the rebound of an elastic mass depends on the hardness of the concrete surface against which the mass strikes. The operation of the rebound hammer is shown in figure-1. The Rebound Hammer Test is a non-destructive method for assessing the strength and surface hardness of concrete. It involves complex principles, mechanics, calibration steps & safety considerations to obtain reliable results.Disadvantages of rebound hammer test. The disadvantages are that the results obtained are based on a local point and it is not directly related to the strength and the deformation property of the surface. The spring and probe arrangement will require regular cleaning and maintenance and the flaws cannot be detected with accuracy. Also Read .

While it is well known that moisture content, surface finishing, and concrete maturity strongly affect the test result, the effect of the stress state has not yet been studied and is found in this research to be a further parameter affecting the test reliability.

One such type of the non-destructive test on concrete structures is the Rebound Hammer Test. The Rebound Hammer test can be defined as the test that is conducted to evaluate the compressive strength of the existing concrete structure particularly for . The Concrete Rebound Hammer Test, also known as the Schmidt Hammer Test, is a widely used non-destructive testing method in the field of construction and civil engineering. This test provides a quick and convenient assessment of the . Schmidt's Rebound Hammer is a nondestructive test which is used to assess the compressive strength of concrete using rebound index. Surface hardness test was done on different concrete.

What is the Rebound Hammer Test? The rebound hammer test, also known as the Schmidt hammer test, checks concrete surface hardness. Developed by Ernst Schmidt in the late 1940s, it is used to measure compressive strength. A spring-loaded hammer strikes the concrete, and the rebound distance is measured to estimate strength. The classic Schmidt rebound hammer is the most popular nondestructive method to measure concrete surface hardness, while the Leeb rebound hammer has been extensively studied in geological and metallographic fields over decades, and its use for testing concrete is almost not known.

leeb hardness tester principle

lame cloture bois autoclave classe 4

The optimal temperature for sterilization typically ranges between 121°C (250°F) and 134°C (273°F), depending on the type of autoclave and the materials being sterilized. At these temperatures, steam penetrates the .

limitations of rebound hardness test|bounce ball hardness testers